While the hull is being laminated, the one-piece deck/deckhouse is also taking shape. Here the deckhouse mold is polished to receive the first layers of fiberglass.The mold is upside down with the window inserts installed. The inserts exactly mirror the windows themselves, ensuring a perfect fit when the part is laminated, removed from the mold, turned right-side up, and the windows are installed and sealed.

That didn’t take long! Now the deck/deckhouse part has been fully laminated and turned upright. The window inserts have been removed and are nearly ready to receive the windows, some of which open while others are fixed. Deck hatch openings and landings, two of which can be seen in the foreground, have also been laminated in place on the forward trunk cabin. Trunk cabin portlights have yet to be installed. Already the wide, flat sidedecks leading to the bow can be seen here in the foreground, helping make the Hunt 80 a highly functional and safety-driven design, as well as being an aesthetically beautiful yacht.

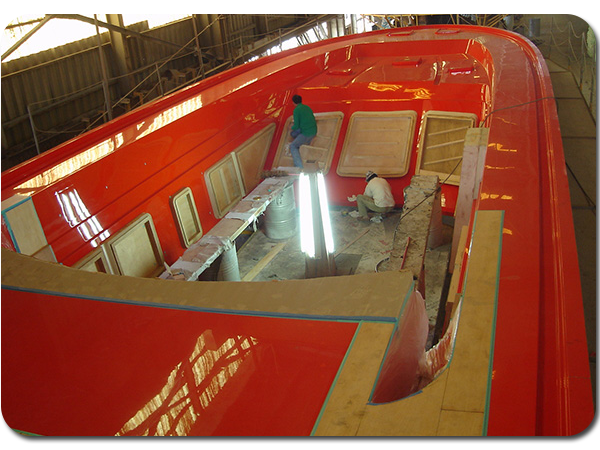

With the yacht’s major systems and related mechanical, plumbing, and electrical components in place, the lower deck has been installed and skilled craftsmen are busy fashioning the interior of the yacht. Bulkheads, partitions, and furniture modules are crafted on the plant floor and then lifted in place and installed.

Now the forward deck/deckhouse unit has been lifted in place for fitting. The hull and deckhouse are in the process of being faired and primed in preparation for final painting. The yacht is shaping up nicely and her final shape is materializing, though much work remains to be done with propulsion drivetrain installation, interior fitting out, and a myriad of other details.